Introduction

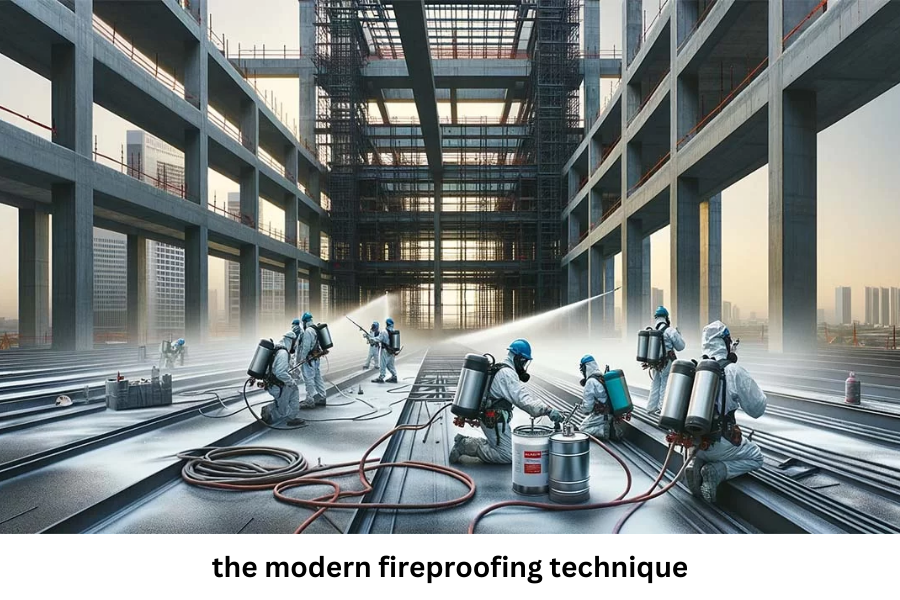

Fire safety in buildings is a critical concern in the modern world, where the frequency of fires and the potential for destruction is ever-present. Whether it’s a residential home, a commercial building, or an industrial site, ensuring that a structure is fire-resistant is an essential part of the design process. Over the years, fireproofing techniques have evolved significantly. This article will explore modern The Modern Fireproofing Technique, discussing the materials, methods, and technologies that are shaping the future of building fire resistance.

What is Fireproofing?

Fireproofing is the process of applying materials and systems to buildings to increase their resistance to fire. The goal is to slow down the progression of a fire, allowing enough time for evacuation or firefighting efforts, and to reduce structural damage. There are various fireproofing methods employed, depending on the type of structure, its purpose, and local building regulations.

The primary objective of modern fireproofing is to:

Protect the structural integrity of the building, preventing the collapse of load-bearing components.

Prevent the spread of fire and smoke, protecting both the building and its occupants.

Enhance the fire-resistance rating of structural elements such as steel beams, concrete, and wood.

Wiki

| Fireproofing Technique | Description | Common Applications | Benefits | Materials Used | Maintenance Needs |

| Intumescent Coating | A coating that expands when exposed to heat, forming a protective insulating layer. | Steel beams, columns, and structures | Provides thermal protection, easy to apply, lightweight, and aesthetically pleasing. | Intumescent paint, coatings, varnishes | Requires periodic inspection to ensure full protection. |

| Cementitious Fireproofing | A spray-on material that provides fire resistance by forming a solid, heat-resistant layer on surfaces. | Structural steel, concrete structures | Cost-effective, durable, and provides high fire resistance for a variety of substrates. | Cement-based mixtures, gypsum, lime | Needs reapplication if damaged or if exposed to moisture. |

| Fire-Resistant Glass | Glass designed to withstand high temperatures and prevent the spread of fire. | Windows, facades, partitions | Maintains structural integrity during a fire, helps to contain fire and smoke. | Fire-resistant glass, laminated glass | Minimal maintenance, check for cracks or damage. |

| Firestopping Materials | Used to seal joints, gaps, and openings in walls and floors to prevent the spread of fire and smoke. | Wall penetrations, joints, gaps | Prevents fire and smoke from spreading through openings. | Mineral-based materials, silicone, graphite, and intumescent sealants | Periodic inspections to ensure no cracks or gaps. |

| Vermiculite-based Systems | Fireproofing panels made from vermiculite, providing fire resistance while being lightweight and versatile. | Ceilings, columns, beams, floors | Lightweight, non-toxic, easy to apply, and cost-effective. | Vermiculite-based compounds, gypsum boards | Can require touch-ups or repairs if damaged. |

| Fire-Resistant Insulation | Insulation material designed to protect against heat and slow the spread of fire by insulating structures. | Pipes, ducts, walls, ceilings | Reduces fire hazards, energy-efficient, provides long-term fire protection. | Mineral wool, fiberglass, ceramic fibers | Periodic checks for wear, especially in high-heat areas. |

| Spray-on Fireproofing | A broad category that includes a range of materials sprayed onto surfaces to provide passive fire protection. | Industrial and commercial buildings | Cost-effective, quick application, suitable for large areas, and provides a good level of fire protection. | Cementitious mixtures, mineral-based compounds, intumescent sprays | May require reapplication in high-traffic or high-risk areas. |

| Passive Fire Protection | Systems designed to prevent the spread of fire and smoke through containment, using fire-resistant walls, doors, and floors. | All types of buildings and structures | Prevents fire from spreading, maintains building integrity during a fire, and provides critical escape time. | Fire-resistant boards, glass, sealants, and barriers | Periodic inspections to check for cracks, gaps, or wear. |

| Active Fire Protection | Includes systems like sprinklers and fire alarms that actively suppress or detect fires. | Commercial buildings, high-rise structures | Detects fires early, suppresses fire growth, and gives occupants time to evacuate or for firefighters to respond. | Sprinklers, smoke detectors, heat detectors, fire alarms | Regular testing and maintenance are required to ensure functionality. |

Materials Used in Modern Fireproofing

Fireproofing materials have come a long way, and new innovations are constantly emerging. Below are some of the most widely used materials in modern fireproofing:

1. Intumescent Coatings

Intumescent coatings are one of the most popular fireproofing materials used in construction today. These coatings are applied to steel, wood, or other structural materials and expand when exposed to heat. When a fire occurs, the coating undergoes a chemical reaction, causing it to swell and form a thick, insulating layer. This layer provides excellent thermal insulation and helps protect the underlying material from the extreme heat of a fire.

Intumescent coatings are particularly useful in buildings with exposed steel elements. Steel, while strong, is vulnerable to heat and can lose its structural integrity quickly in high temperatures. Intumescent coatings provide a fire resistance rating of up to four hours, depending on the thickness and type of material used.

2. Cementitious Fireproofing

Cementitious fireproofing involves the application of a spray-on material that has a cement-like consistency. These materials are often used to protect structural steel and concrete elements in commercial and industrial buildings. Cementitious fireproofing materials are easy to apply and can be applied in large quantities, making them cost-effective for large-scale projects.

These materials are typically made from a mixture of water, cement, and insulating aggregates such as perlite or vermiculite. Once applied, the coating hardens and provides a durable fire-resistant barrier. The key advantage of cementitious fireproofing is that it can be easily repaired and re-applied, which is important in maintaining fire protection over time.

3. Vermiculite-Based Systems

Vermiculite is a naturally occurring mineral that has been used for decades as a fireproofing material. When exposed to high heat, vermiculite expands significantly, creating an insulating barrier that prevents heat from reaching the underlying material. Vermiculite-based fireproofing systems are commonly used for the protection of steel and other metals in buildings.

Vermiculite is often mixed with other materials, such as gypsum, to create a sprayable fire-resistant coating. These systems are lightweight, cost-effective, and easy to apply. However, they are not as durable as other fireproofing methods and may require reapplication over time.

4. Fire-Resistant Boards

Fire-resistant boards are an essential component in modern fireproofing techniques. These boards are typically made from materials like calcium silicate, gypsum, and mineral fiber, which are designed to withstand high temperatures. Fire-resistant boards are used to protect various structural components, including walls, ceilings, and floors.

These boards can be installed as part of a fire-resistant wall system or as an individual component to protect specific areas. They are particularly useful in compartmentalizing buildings to prevent the spread of fire from one area to another. The fire resistance of these boards can range from one to four hours, depending on their thickness and composition.

5. Fire-Resistant Glass

In modern architecture, large glass windows and facades are becoming increasingly common. However, glass is a highly flammable material and can break under intense heat. To address this, fire-resistant glass has been developed.

Fire-resistant glass incorporates intumescent layers or wire mesh to provide protection against the spread of fire and smoke. These glasses are designed to maintain their structural integrity during a fire, preventing flames from breaking through and allowing for safe evacuation. Fire-resistant glass is typically used in doors, windows, and partitions in both commercial and residential buildings.

6. Firestopping Materials

Firestopping materials are used to seal gaps and openings in fire-resistant walls and floors. These openings are typically created by the installation of electrical cables, pipes, or ducts. Firestopping materials are essential for preventing the spread of fire and smoke through these openings.

Firestopping materials are made from a variety of substances, including silicone, intumescent materials, and mineral fibers. These materials expand when exposed to heat, filling any gaps and preventing the passage of flames and smoke. Proper installation of firestopping materials is crucial for ensuring the overall fire resistance of a building.

Fireproofing Techniques: Methods and Applications

Modern The Modern Fireproofing Technique not only rely on materials but also on the application methods and technology that enhance their performance. Here are some of the techniques that are commonly employed:

1. Spray-Applied Fireproofing

Spray-applied fireproofing is one of the most common methods used for fireproofing structural steel and concrete elements. In this technique, fire-resistant materials such as cementitious or intumescent coatings are sprayed directly onto the surface of the structure. The spray can be applied quickly and efficiently, covering large areas in a short amount of time.

Spray-applied fireproofing is especially useful in commercial and industrial buildings where large amounts of structural steel need to be protected. It is also a cost-effective solution for many building types, as it does not require the installation of additional fire-resistant layers.

2. Fireproofing by Encapsulation

Encapsulation involves encasing a structure with fire-resistant materials. This method is commonly used for structural steel, which is often wrapped in fire-resistant blankets, boards, or coatings. The goal of encapsulation is to completely cover the material in a layer of fire-resistant substance, creating a barrier between the heat of the fire and the underlying structure.

Encapsulation is particularly useful for steel columns, beams, and other load-bearing elements, which are susceptible to heat damage. This method ensures that the material can maintain its structural integrity for longer during a fire, preventing collapse.

3. Fireproofing with Fire-Resistant Insulation

Fire-resistant insulation materials, such as mineral wool or fiberglass, can be used to insulate buildings and reduce the risk of fire. These materials are applied to areas where heat is most likely to accumulate, such as attics, ducts, and walls. Fire-resistant insulation helps prevent the spread of fire and also provides thermal protection to keep areas cooler during a blaze.

Insulation is commonly combined with other fireproofing techniques, such as fire-resistant boards or intumescent coatings, to create a comprehensive fire-resistant system.

4. Passive Fire Protection Systems

Passive fire protection (PFP) refers to the use of fireproofing materials and design features that limit the spread of fire and protect the structure without requiring active intervention, such as sprinklers or alarms. Examples of passive fire protection systems include fire-resistant walls, floors, doors, and ceilings. These elements are designed to contain fires and limit their impact, providing valuable time for evacuation and firefighting efforts.

5. Active Fire Protection Systems

While passive fire protection focuses on containment, active fire protection systems, such as sprinklers and fire alarms, actively detect and suppress fires. These systems work alongside passive protection measures to provide a multi-layered approach to fire safety. Active systems can significantly reduce the severity of fires and provide critical time for evacuation.

6. Water Mist Systems

Water mist systems are a modern fire suppression technique that uses fine water droplets to suppress fires. Unlike traditional sprinkler systems, which use large volumes of water, water mist systems use significantly less water, reducing the potential for water damage. Water mist systems are effective in controlling fires in sensitive environments, such as data centers, where traditional sprinklers might cause more harm than good.

Challenges in Fireproofing

Despite the advancements in The Modern Fireproofing Technique, several challenges remain. One of the biggest challenges is the maintenance of fireproofing systems. Over time, fireproofing materials can deteriorate or become damaged, which compromises their effectiveness. Regular inspections and maintenance are essential to ensure that fireproofing systems remain intact.

Another challenge is the cost of fireproofing. While fire-resistant materials are essential for building safety, the costs associated with applying and maintaining fireproofing systems can be substantial. Developers and building owners must balance the need for fire protection with budget constraints.

Lastly, the complexity of modern building designs can pose a challenge for fireproofing. With the increasing use of glass, open spaces, and complex floor plans, it can be difficult to ensure that every area of the building is adequately protected. The Modern Fireproofing Technique must be customized to meet the specific needs of each building design.

Conclusion

In today’s world, where safety is paramount, the modern The Modern Fireproofing Technique has become an integral part of building design and construction. Whether it’s protecting a commercial skyscraper or a residential home, fireproofing ensures that structures are resilient in the event of a fire, offering valuable time for evacuation and firefighting efforts. The innovations in materials such as intumescent coatings, cementitious fireproofing, and fire-resistant glass have revolutionized how we approach fire safety.

Modern The Modern Fireproofing Technique go beyond just protecting structural elements; they incorporate advanced systems that minimize fire damage, prevent the spread of smoke and flames, and ensure that a building can withstand extreme conditions. With a combination of passive and active fire protection systems, buildings can meet the demands of modern architecture while prioritizing safety.

However, with new technologies come new challenges, such as the need for regular maintenance, the complexity of modern designs, and the cost involved. Despite these challenges, ongoing advancements in fireproofing technologies ensure that we are better equipped than ever to deal with fire-related hazards. As fireproofing continues to evolve, it will remain a critical part of designing safer, more resilient buildings for the future.

FAQs

1. What is fireproofing, and why is it important?

Fireproofing is the process of applying materials and systems to a building or structure to enhance its resistance to fire. It is crucial for protecting both the structure and its occupants by preventing the rapid spread of flames and smoke, maintaining the integrity of structural elements, and providing more time for evacuation or firefighting.

2. What are the common materials used in modern fireproofing?

Modern fireproofing materials include intumescent coatings, cementitious fireproofing, vermiculite-based systems, fire-resistant boards, fire-resistant glass, and firestopping materials. These materials are chosen for their ability to withstand high temperatures and prevent the spread of fire.

3. How does intumescent coating work?

Intumescent coatings are applied to structural elements such as steel. When exposed to high heat, the coating undergoes a chemical reaction and expands, forming a thick, insulating layer that protects the underlying material from the intense heat of a fire.

4. What is cementitious fireproofing, and where is it used?

Cementitious fireproofing involves spraying a cement-like mixture onto structural materials such as steel and concrete. This coating provides a durable, fire-resistant barrier that helps protect structural elements from high temperatures. It is commonly used in commercial and industrial buildings.

5. Can modern fireproofing materials withstand extreme temperatures?

Yes, many modern fireproofing materials are designed to withstand extreme temperatures. For example, intumescent coatings can provide protection for several hours, while cementitious fireproofing and fire-resistant boards can also endure high heat, significantly slowing the progression of a fire.

6. What are passive and active fire protection systems?

Passive fire protection refers to building elements such as fire-resistant walls, floors, and doors, which help contain a fire and prevent its spread. Active fire protection systems, such as sprinklers and alarms, actively detect and suppress fires, working alongside passive systems to provide a comprehensive fire safety strategy.

7. Are modern The Modern Fireproofing Technique expensive?

While fireproofing materials and systems can be costly, their benefits far outweigh the risks of fire damage. The price of fireproofing varies depending on the materials used and the complexity of the building design, but investment in proper fireproofing is essential for long-term safety.

8. How often should fireproofing systems be maintained?

Fireproofing systems should be inspected regularly to ensure they remain effective. Over time, materials can deteriorate due to environmental factors or physical damage, so maintenance and reapplication may be necessary to keep the fire protection intact.

9. Can modern fireproofing methods be used in all types of buildings?

Yes, modern fireproofing techniques can be adapted to suit a wide range of building types, from high-rise commercial structures to residential homes. The choice of materials and methods depends on the specific needs and design of the building.

Get the latest scoop and updates on playhop